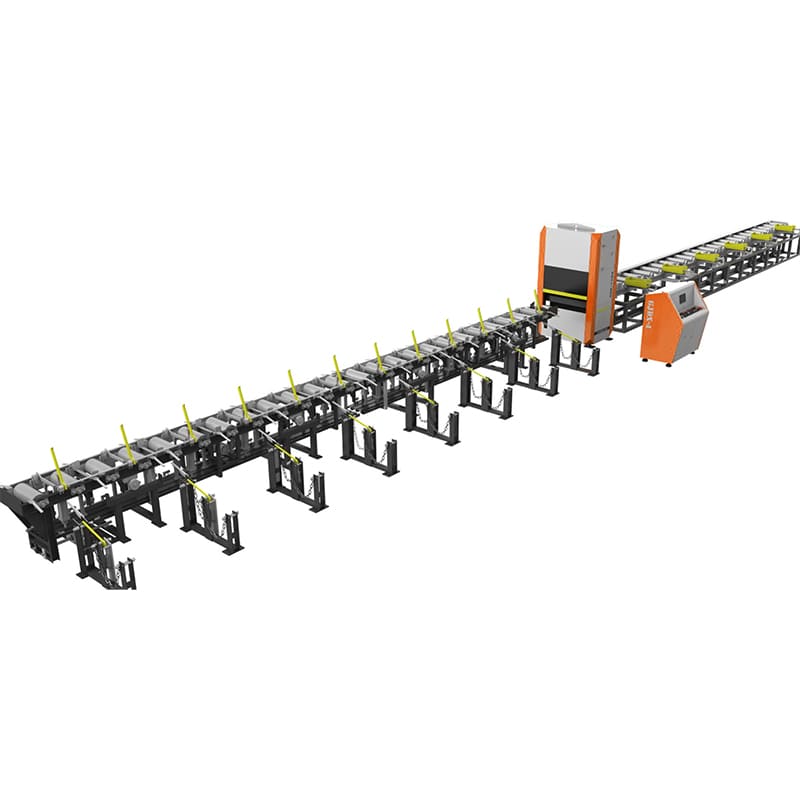

Steel Bar Shearing Line

Bar Diameter: φ10-40mm

Feed Speed: 40-60m/min

Cut Length: 700-12000mm

Cut Tolerance: ±5mm

Cut Speed: 30 time/min

Size: 26000*4500*1500

500/800 Steel Bar Shearing Line

Steel Bar Shearing Line is designed for high-speed and precise cutting of steel bars, making it perfect for large-scale construction and manufacturing projects. This machine combines speed and precision, offering cutting speeds between 6 and 10 seconds per cut. With the ability to handle bar lengths from 2 to 12 meters, it achieves a balance of efficiency and accuracy, ensuring high-quality performance in demanding environments.

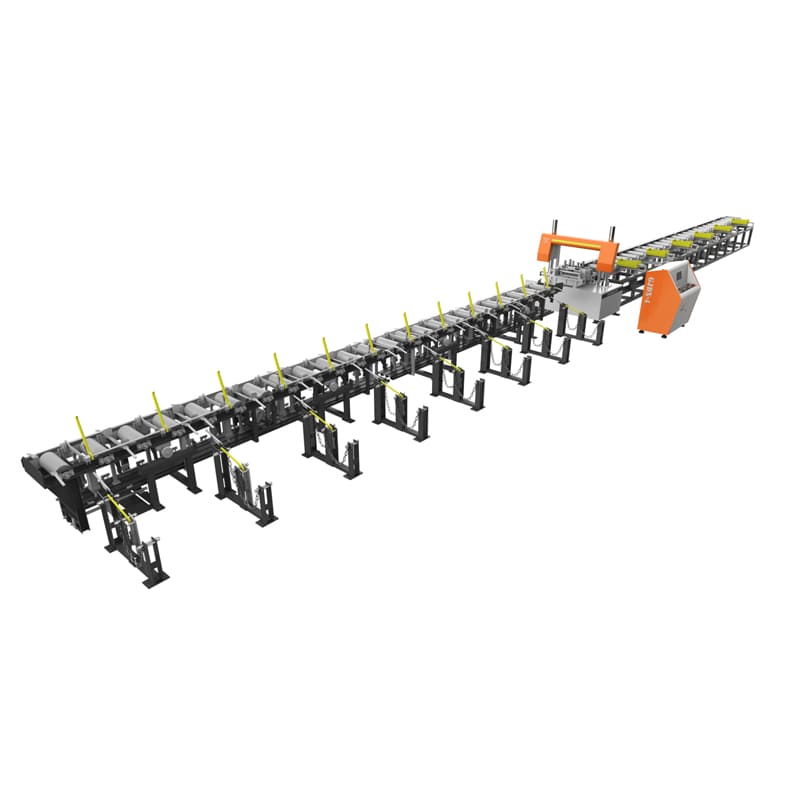

Key Features:

High-Speed Cutting

Achieves cutting cycles in just 6–10 seconds, delivering clean, accurate shearing that maximizes productivity on the job site or in the factory.

Wide Cutting Range

Handles steel bars ranging from 2 to 12 meters in length, with a processing width of 450–500mm, making it ideal for a variety of construction and fabrication needs.

Fast Material Handling

With a transmission speed of 0.8–0.9 m/s, the system ensures rapid and precise bar positioning, significantly improving material throughput.

Millimeter-Level Accuracy

Delivers exceptional cutting precision with millimeter-level tolerance, helping reduce waste and improve material utilization.

Enhanced Production Capacity

Capable of processing multiple bars simultaneously, the system features a dual-side unloading mechanism for uninterrupted, high-efficiency operation.

Reliable Clamping System

Uses a combination of hydraulic and pneumatic clamping, securing the bars firmly in place during cutting for stable and safe operation.

Seamless Integration

Easily connects with downstream threading or bending lines, enabling fully automated rebar processing from start to finish.

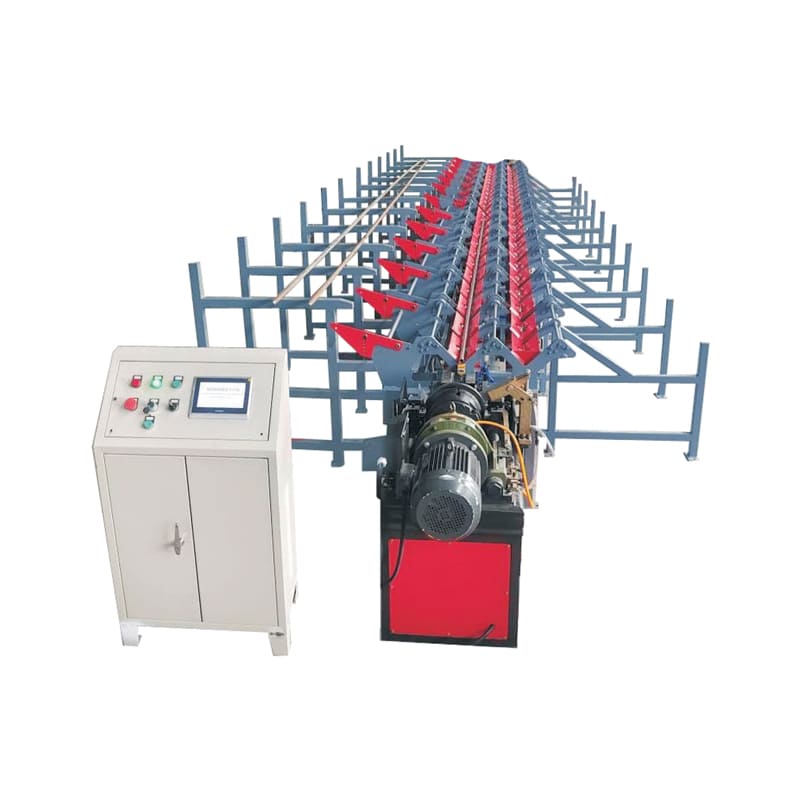

| Heavy-Duty Rebar Cutting Machine Specifications | |

|---|---|

| Cutting Performance | |

| Feed Speed | 40-60 m/min (131-197 ft/min) |

| Cutting Speed | 30 cuts/minute |

| Cut Length Range | 700-12,000 mm (27.6-472.4 in) |

| Cut Tolerance | ±5 mm (±0.2 in) |

| Blade Specifications | |

| Blade Width | 260 mm (10.2 in) |

| Minimum Cut Length (Manual) | 10 mm (0.4 in) |

| Minimum Cut Length (Automatic) | 700 mm (27.6 in) |