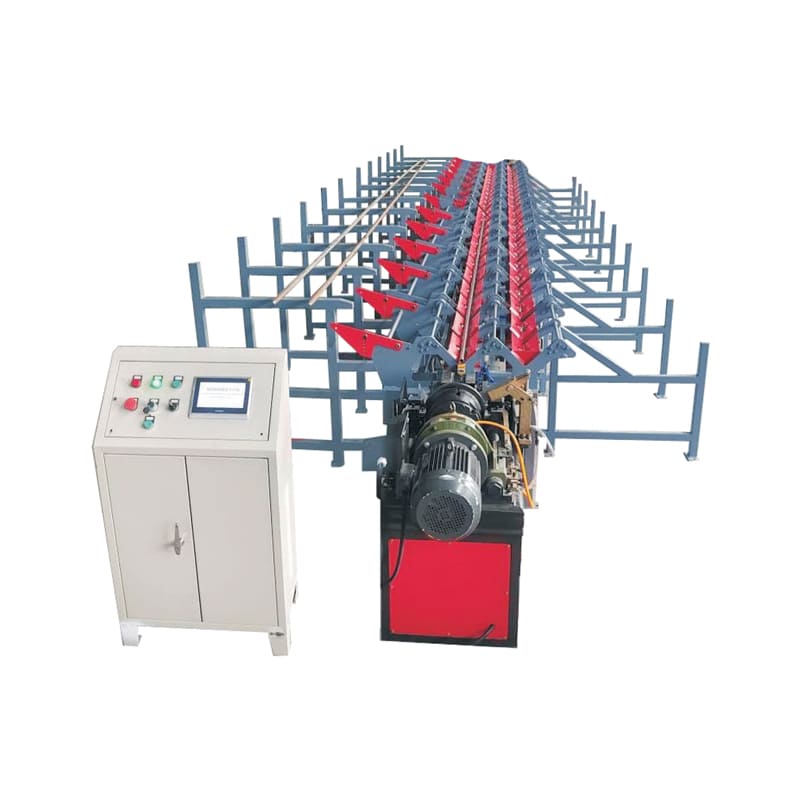

Steel Bar Threading Line

Rebar Diameter: Φ16~Φ40(mm)

Rebar Length: 2-12m

End Length: 80mm

Rebar Feed Speed: 22m/min

Total Power: 22kw

Threading Motor: 7.5kw*2

Power Consumption: 8KW/H

Size:13000*3000*1300mm

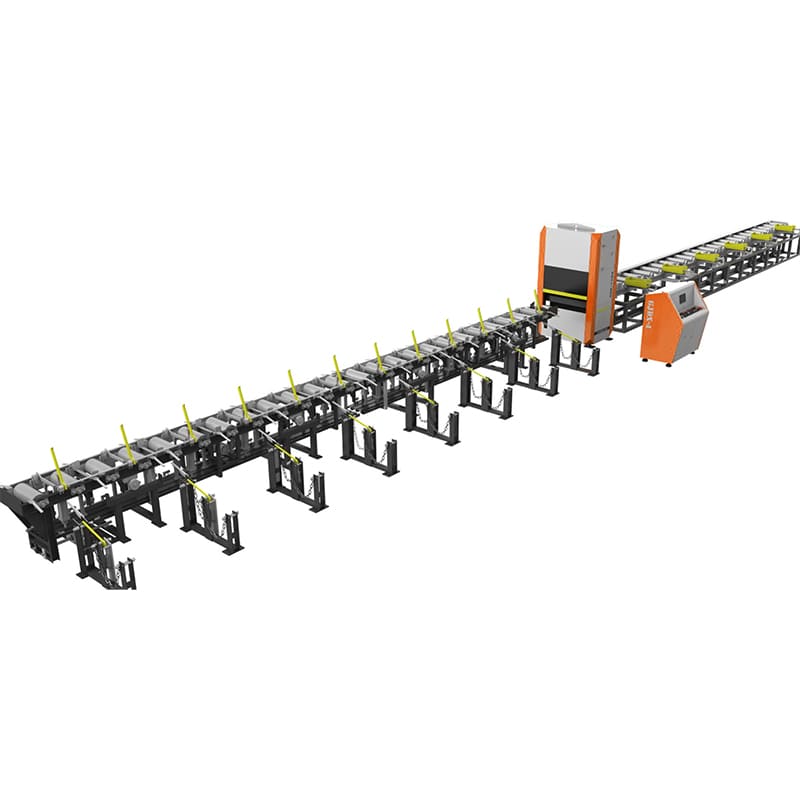

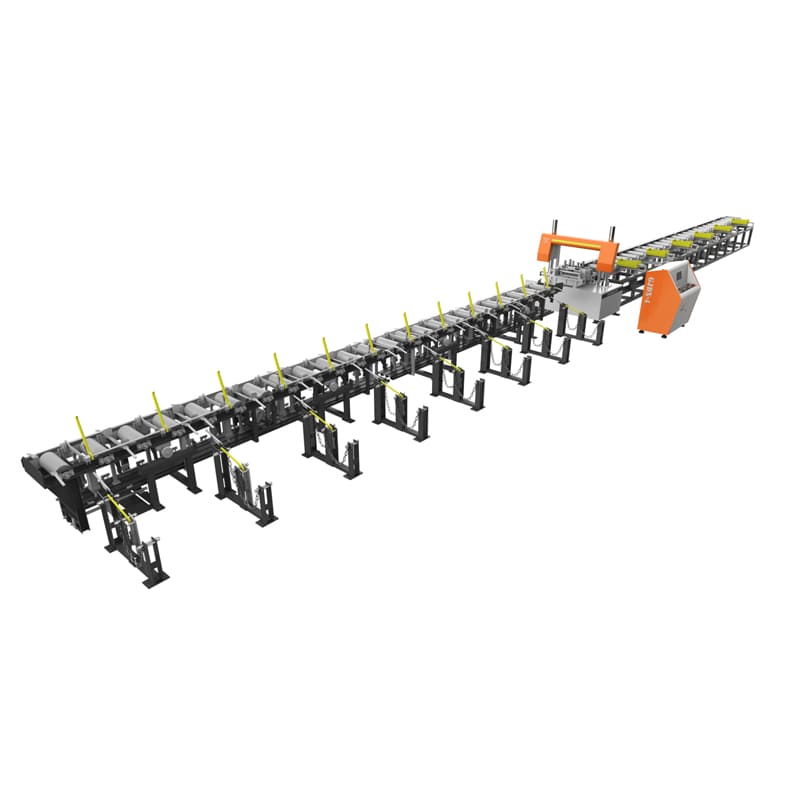

CNC Simple Steel Bar Threading Line

CNC Simple Steel Bar Threading Line is a cutting-edge solution designed to optimize steel bar processing with high precision and efficiency. This advanced system includes essential components such as a material preparation rack, a feeding platform, two threading machines, a storage platform, and a digitally controlled electric cabinet for seamless automation.

Threading Line Specifications:

CNC Simple Steel Bar Threading Line |

|

|---|---|

| Rebar Specifications | |

| Diameter Range | Φ16-Φ40 mm (0.63-1.57 in) |

| Length Range | 2-12 m (6.56-39.37 ft) |

| Minimum End Length | 80 mm (3.15 in) |

| Performance | |

| Feed Speed | 22 m/min (72 ft/min) |

| Power System | |

| Total Power | 22 kW (29.5 HP) |

| Threading Motors | 7.5 kW × 2 (10 HP × 2) |

| Power Consumption | 8 kWh |

| Physical Dimensions | |

| Machine Size | 1300 × 3000 × 1300 mm (51.2 × 118.1 × 51.2 in) |

Threading Line Key Features and Benefits:

Automated Efficiency

Designed to support rebar diameters from 16mm to 50mm and strength grades including HRB335, HRB400, and HRB500, this system integrates electrical, hydraulic, and pneumatic technologies for fast, stable operation.

The automated process reduces manual intervention, ensuring consistent performance and high daily output across all production stages.

Advanced Material Handling

Equipped with a high-capacity storage rack and an automated bar feeding platform, the line minimizes labor requirements while maximizing workflow efficiency.

Durable, noise-reducing V-shaped rollers ensure smooth transport of steel bars, while the main processing head performs clamping, feeding, diameter reduction, and thread rolling automatically—delivering precise, high-quality threads with every cycle.

High Production Capacity

-

Capable of producing up to 1,000 wire heads per shift

-

Processes 400 to 500 steel bars in just 10 hours

-

Ideal for large-scale projects and tight deadlines

-

Maintains millimeter-level accuracy throughout continuous operation

Conclusion:

CNC Simple Steel Bar Threading Line is an efficient and high-capacity solution for steel bar processing. With advanced automation, low maintenance, and superior productivity, it’s an ideal choice for construction and industrial applications requiring fast and precise threading.